Mixer with vertical feed 6 m³

Product Features:

1. High-strength wear-resistant plate, resistance tank body,

2. The blade is coated with tungsten carbide alloy for long service life.

3. Super-strong double reduction system, stable operation

4. Frequency conversion start one piece of material removal, zero residue

B. Product specifications: 3-60 cubic meters can be customized

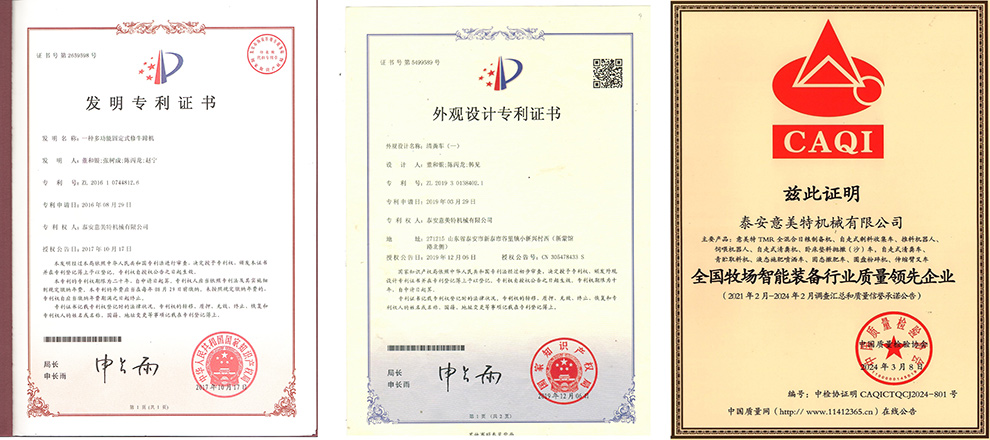

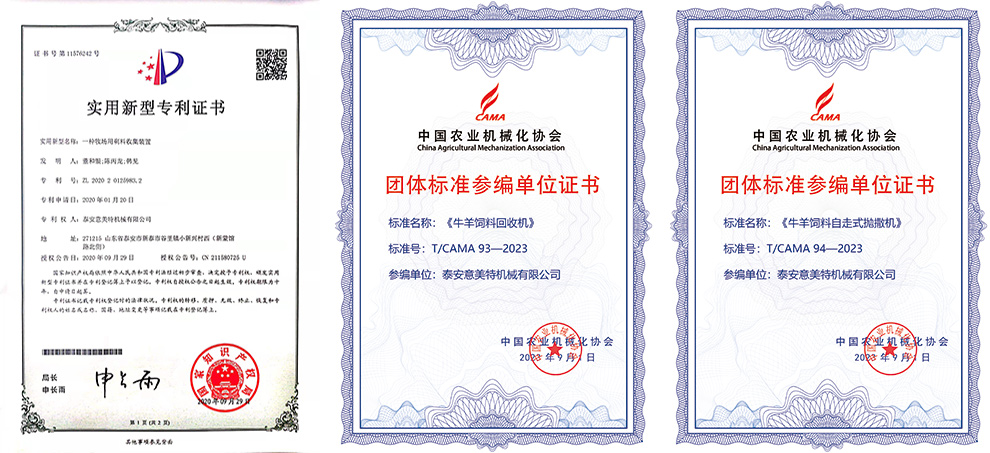

C. Patented product: has 4 inventions, appearance and use of new patents

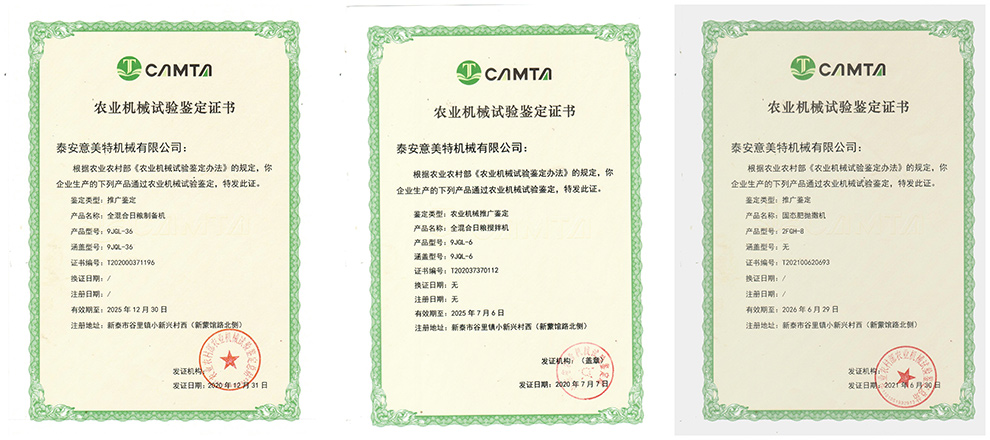

D. National Agricultural Machinery Subsidies Promotion Products: Two Series and 13 Specifications

Product description:

The vertical feed mixer is mainly powered by electricity with a shovel and spreader to complete the feeding operation.

The mixer is suitable for: dairy cows, beef cattle and large sheep farms, can be a variety of pasture, straw, silage and other fibrous feed mixing and mixing, after feeding.

9JGL series complete ration mixer is a vertical stationary equipment, the feed mixing method takes the form of spiral vertical whipping mounted on blades with blades, used to cut all kinds of hay, low noise, less environmental pollution. There is a discharge device on the side of the box, the discharge door is closed when the stationary mixer is mixing, and the discharge door is opened to discharge the feed after mixing. On the rear side of the stationary mixer there is a loading device (can be custom-made) that controls the hydraulic system.

The feed is added in the following order: first long, then short, first light, then heavy, first dry, then wet, first coarse, then fine.

The order of mixing and adding feed is: long grass (sheep grass, alfalfa, oats, etc.) → silage (corn silage, barley) → by-products (cottonseed, beans, beet meal (BME), brewers meal, etc.) → with concentrate → water or molasses.

Advantages of the TMR vertical feed mixer:

1. Simple design:

Simple design; More accurate weighing; Easily handles large round or square bales of hay; Wear on the concrete mixer truck is significantly reduced due to low feed pressure on the side walls of the barrel.

Vertical feed mixers have a simple design. Unlike horizontal mixers, they have more parts and require more careful maintenance. Furthermore, more parts mean a higher risk of failure, which negatively impacts proper operation.

The mixing effect of the vertical mixer is more uniform and precise. The reason is that the feed is mixed by the winch and then falls down naturally, so the mixing effect is very good.

A vertical mixer easily handles large sacks of feed. Most horizontal mixers struggle with large round or square sacks of feed, while vertical mixers can easily mix them.

Since the pressure on the bottom and side walls of a vertical mixer tank is very low, the equipment wears out very slowly. Horizontal mixers do not have this advantage and wear out faster, resulting in a shorter service life.

2. Good mixing effect:

After mixing, the feed becomes soft and pleasant to the taste; the feed does not clump easily; since the winch rotation speed is slow, damage to the fibrous structure of the feed is minimal.

The vertical mixer mixes soft and tasty feed, which increases the cows' appetite and is easily digestible.

Feed mixed with a vertical mixer is not easy to clump. Clumping refers to the formation of dry and hard lumps due to excessive extrusion of feed, causing cows to always feel full and unable to eat much. Horizontal concrete mixer trucks easily overpress the feed due to the horizontal structure of the winch, while this situation does not arise with vertical concrete mixer trucks.

Due to the low rotation speed of the winch, the vertical mixer causes less damage to the fibrous structure of the feed. If the fiber structure is damaged, nutrients are quickly lost. Compared to horizontal mixers, vertical mixers can retain feed nutrients for a longer period of time.

To summarize, vertical mixers have a simple design and are more reliable. They cover the entire process from mixing to unloading to ensure high-quality feed is mixed, which improves milk production and quality. For these reasons, we recommend vertical mixers.

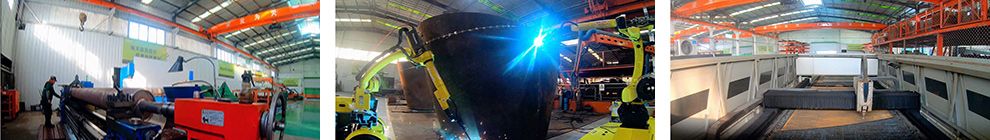

Company strength

With honors